Measuring the temperature of your fridge and freezer and setting up alerts for temperature breaches is crucial to ensure goods are stored correctly. This is especially important for perishable items like food and medicine, as they stay fresher for longer when stored at the right temperatures.

Companies in various industries must adhere to regulatory standards to prevent any potential harm from incorrect storage conditions. According to the Food Standards Agency it is a legal requirement that chilled food is stored below 8°C, with fridges ideally set at 5°C and below. Regular temperature checks and record-keeping are essential for due diligence.

In the life science industry, refrigeration is also vital for storing samples at the correct temperatures to ensure accurate research results.

By utilising various methods to measure temperature and set alarms, you can proactively address any issues before goods are compromised.

What are the different ways to measure temperature and set alarms?

Receiving an early warning about a temperature anomaly within your appliance is crucial, providing you with valuable time to assess and address the issue before goods are spoilt and losses incurred.

One way to achieve this is by using thermometers that not only display the temperature on a screen but also emit an audible alarm when fridge/freezers temperatures surpass a specific threshold. However, for compliance purposes, it is essential to manually record these temperature readings.

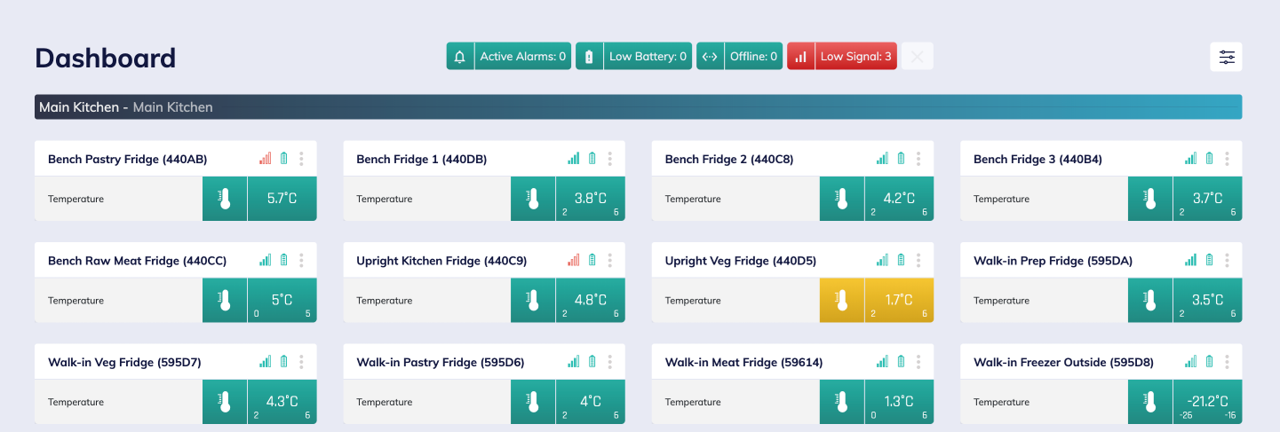

Alternatively, there are more advanced solutions that alert staff on their PC, Laptops and Smartphones by initiating a telephone call, sending a text message or email. These automated solutions often use wireless IoT sensors and help to fulfil compliance obligations by automatically recording the temperature of your appliances 24/7 on an online platform.

Alternatively, there are more advanced solutions that alert staff on their PC, Laptops and Smartphones by initiating a telephone call, sending a text message or email. These automated solutions often use wireless IoT sensors and help to fulfil compliance obligations by automatically recording the temperature of your appliances 24/7 on an online platform.

What should you take into account when evaluating these approaches?

While thermometers are appealing due to their low cost, they may not address all the challenges you encounter when implementing them. So, what other factors should you consider?

Compliance – Do you need to take temperature readings for compliance? Can this be done manually or is a system-based solution required?

Resource – Do you have the resources to manually monitor appliance temperatures? How much will this cost in terms of salaries, and can you ensure accurate and reliable monitoring? Who will be responsible, and how will it be managed?

Cost of goods stored – What is the cost of replacing stored goods, and how long will it take to replace, if goods are spoilt due to a temperature issue? How will this impact your customers?

Night-time faults – Will a local fridge alarm be heard during the night?

Power cuts – What impact will power outages have? How will you be notified if they occur at night, and how will this affect your stored items?

Reputation – How will a quality issue affect your reputation?

Content quality – Fluctuating fridge/freezer temperatures throughout the day and night make it challenging to determine if appliances are consistently in the safe zone, impacting the quality of stored items.

Alarm fatigue – Are there instances where false alarms may be triggered, such as when restocking appliances? Is there a risk of alarms being disabled as a result?

What are the key advantages of adopting an automated solution?

Automated monitoring solutions also measure the temperature of your appliances and promptly alert your team when temperature thresholds are exceeded. These innovative solutions provide a comprehensive approach to temperature monitoring. So, what are the key advantages of utilising this advanced technology instead of traditional thermometers?

Compliance - The temperature data collected is accurate and reliable, automatically recorded in dashboards and charts. Generating reports is effortless, and data can be easily stored on a network or PC, eliminating the need for manual paperwork. This streamlines compliance efforts, making it less burdensome for your staff.

Resource - With automated monitoring, there is no need to allocate resources for manual temperature readings or spend time overseeing the process. This frees up your staff to focus on more critical tasks that align with their skills and expertise.

Cost of compliance – this is typically less using an automated monitoring solution compared with using thermometers, once you factor in the time it takes to take temperature readings of all your appliances. Peoples’ salaries are the biggest cost here and are best allocated to tasks that bring greater value to your business.

Night time faults & power cuts - Instant alerts can be sent to you and your team via smartphones to address temperature breaches promptly, even during night-time hours. Detailed temperature history charts provide certainty on whether stored contents are safe or need to be discarded.

Alarms - These solutions offer a range of alarm settings, both basic and advanced, to assist your response team in managing alerts effectively.

Ensure content quality - With an automated solution, it’s easy to ensure that appliances remain within the safe temperature range. Temperature fluctuations are easily monitored through charts, enabling timely adjustments if needed.

Reduce energy costs - Adjusting settings, if set too high, can help reduce energy consumption and lower costs.

Access to data centrally - With an automated monitoring solution, data is stored centrally providing you with access to your appliance temperature readings in seconds. What's more the solution can be expanded to measure the conditions in other parts of the premises and help you to manage other challenges like legionella control, energy consumption, CO2 and more.

Conclusion

While fridge thermometers can assist in measuring fridge temperature, utilising them to meet regulatory standards requires the traditional method of pen and paper. On the other hand, system-based solutions offer automated, accurate, reliable, efficient, and cost-effective temperature monitoring. If you find yourself in a bustling environment with limited time to spare, isn't it time to transition to a more advanced, automated solution?

If you would like a demonstration, pricing or more information about our temperature monitoring solution, please get in touch with us. You can find all our contact details by clicking on the contact us tab at the top right of this page.